Date : 10.1.2012 (Tuesday)

Time : 8:30am to 11.30am

Topic : KMAM

Person in charge : Mr. Rahimy and Mr. Izhar

KMAM (Kawalan Mutu Air Minum) : Water Treatment Plant

It was a fruitful day as we learned about KMAM today. Before heading to our field trip, we were briefed by Mr. Rahimy about water treatment plant. KMAM which stands for Kawalan Mutu Air Minum functions to ensure the production of safe water which meets the National Water Quality Guidelines 1983 of safe drinking water for the public. The treated water should be safe, palatable and aesthetically appealing and can be use for all purposes. After the brief introduction, we then headed to our destination which is the Loji Pembersihan Air Pelubang, Jitra.

It was just a short 10 minutes journey from Pusat Kesihatan and we have reached our destination.

The Pelubang Water Treatment Plant is the biggest in the state of Kedah. It was constructed in the year of 1984 and began to operate in 1987. It is located in Kubang Pasu district, which is about 11km from Jitra town and has a capacity to provide 60 million gallons of clean water per day to Kubang Pasu and northern part of Kota Star and Pendang.

Upon arriving, we were briefed by Mr. Izhar Ismail who is a lab assistant working there.

The process of water treatment in Pelubang :

Raw water from Sg. Padang Terap (the main source of raw water) is taken by the raw water pump and transferred to the mixing channel (bangunan kimia) where the first chemical, liquid aluminium is added. This process is to reduce the turbidity of the water. The NTU (Nephelometric Turbidity Unit) of the water after this process must be less than 15. Then, the water enters the sedimentation tank for removal of suspended solids trapped in the floc. Subsequently, the water is sent for filtration. After filtration, chlorine, hydrated lime and sodium siloco fluoride are added to the water to stabilize the pH. The pH is maintained between 7.5-8.5. Then, the treated water reach clear water well and the NTU must be less than 5 by this time. It is then transferred and stored in the reservoir by clear water pump. The 2 reservoirs for Pelubang Water Treatment Plant are Bukit Tinggi and Bukit Mengkuang. Water from reservoir supplied to premises.

*********************************************************************************

After knowing about water treatment process, we were brought to the lab by Mr. Izhar.

Various tests are done to ensure the quality of the treated water. Firstly, Mr. Izhar showed us the method to test for turbidity of water using turbidimeter. He told us that the turbidity of raw water varies according to weather. It may be as high as a few hundred in raining season while less than one hundred if there is no rain.

The turbidity of settled water is 4.89 NTU.

The turbidity of treated water is 0.78 NTU.

Then, he showed us the method to test for chlorine content in the water. Firstly, DPD free chlorine reagent is added to 10 ml of sample water. The sample changed colour and it was then placed in a machine to check for its chlorine content.

The chlorine level for the sample is 2.65mg/L which is too high. It should be in the range of 1.5-2.5.

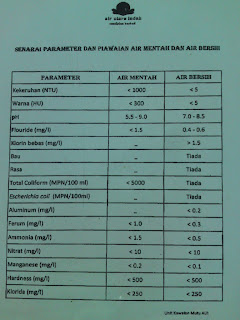

Subsequently, Mr. Izhar told us about the other examinations which should be done to maintain the quality of the treated water. Treated water is checked two hourly daily, weekly and also monthly for different parameters. Parameters which are checked for every two hourly include turbidity, colour, pH, fluoride, free residual chlorine, total coliforms and E. coli.

Magnesium and iron content are checked weekly.

This is the standard parameters for raw water and treated water.

Later, we were brought to visit the water treatment plant.

The end.

Prepared by,

Loh Swee Hong

No comments:

Post a Comment